| High melting point and density, low thermal expansion, good thermal and electrical conductivity, excellent heat and corrosion resistance, unique radiation shielding property and outstanding purity from Refractory Metals, is what we are exploring to satisfy specific requirements in our customers applications.

Our materials of molybdenum and tungsten are produced by powder metallurgical methods with close to theoretical density and extremely fine grain structures, and materials of tantalum, niobium, zirconium, hafnium and chromium are produced by vacuum melting, all materials with high purity above 99.95% are helpful to us to obtain ideal physical performance and meet the requirements of each individual application in the exotic areas.

Molybdenum |

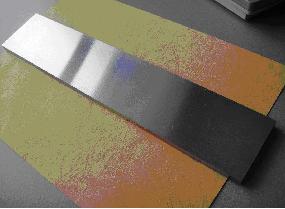

Pure molybdenum is an element of atomic number 42, with density 10.28g/cm3 and melting point 2620°C (4748F), it is metal shine with silver grey and weakly to be oxidized in atmosphere, normally carbide tool is recommended for machining as of hardness HV220. Due to its high temperature strength, low thermal expansion, good thermal conductivity, typical applications including: heat radiation shielding for vacuum furnace, power semiconductor substrate, glass sealing and melting, components and assemblies for thin film coating devices, ION implanting system. |

|

TZM(Titanium-Zirconium-Molybdenum) |

|

Our material of TZM alloy are contented with Ti (0.40-0.55%) and Zr (0.06-0.12%), with small quantities alloying, it increases the re-crystallization temperature by 250°C and perform stronger high temperature strength comparison with pure molybdenum. The finer grain structure of TZM and the formation of TiC and ZrC in the grain boundaries offer better properties of formation and welding abilities. Typical use for TZM are furnace structural components, nozzles, forging tools, rotating anode in X-ray tubes. |

|

MoLa (Molybdenum-Lanthanum Oxide) |

|

MoLa (Molybdenum-Lanthanum Oxide) from Pan-Ocean is produced by sintering with pure molybdenum powder and doped with lanthanum oxide particles (La2O3 0.5-0.7%), this oxide-dispersion strengthened molybdenum is a mixture of molybdenum with a very fine array/dispersion of lanthanum oxide particles, which results in extraordinary resistance to re-crystallization, ductility, and high-temperature deformation. It is an ideal material for applications requiring dimensional stability and strength at temperatures above the capabilities of either pure Molybdenum metal or Molybdenum-TZM alloy. MoLa are preferred for applications in the range of 1200°C up to 1850°C. |

|

Standard items from Pan-Ocean on Molybdenum and Molybdenum alloy

| Material Type |

Dimensions |

Thickness mm |

Width mm |

Length mm |

Forged |

Bar |

Dia.200-100 |

|

600 |

Dia.100-60.0 |

|

1000 |

Dia.60-30 |

|

2000 |

Rod |

Dia.10.0-15.0 |

|

6000 |

Dia.3.0-10.0 |

|

6000 |

wire |

Dia.0.1-6.0 |

|

coil |

Rolled |

Plate |

>3.0 |

400 |

L |

Sheet |

1.0-3.0 |

400 |

1000 |

0.20-1.0 |

350 |

1000 |

0.1-0.20 |

200 |

600 |

Foil |

0.05-0.1 |

100 |

500 |

Fabricated |

Components |

hot zone, power semiconductor substrate, glass sealing and melting electrode, components and assemblies for thin film deposition system, ION implanting system, X-ray tube anode, heat sink. |

Tungsten |

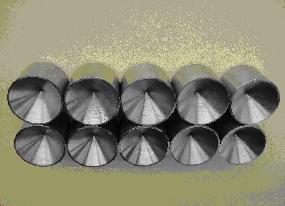

Tungsten is a metal with highest melting point of 3420°C(6188K) and density of 19.3g/cm3, It is also characterized by a uniquely low coefficient of thermal expansion, Tungsten is therefore very suitable for high-temperature applications. Pan-Ocean uses this materials to manufacture heating elements for high temperature furnace, medical radiation shielding, components and assemblies for thin film deposition system as well as ION implanting systems. The most of tungsten mines was found in China. |

|

Tungsten Carbide |

|

The high hardness is another important property of tungsten metal, and tungsten carbide is the major usage of tungsten which made by sintered with compounds of WC, TiC and adhesives. There are many types of tungsten carbide, the most popular applications are used to produce various tools. Pan-Ocean use ready tungsten carbide materials to manufacture cutters, inserts, balls, dies, and sealing, etc. |

|

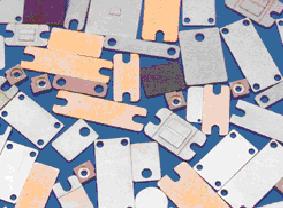

Tungsten Copper |

|

Tungsten copper alloy is a pseudo-alloy of tungsten and copper, the material is composed of distinct particles of tungsten and copper. The microstructure is showing a metal matrix composite, therefore it performs the properties of both heat-resistant by tungsten and ablation by copper. It can be more easier to be machined than pure tungsten, so suitable applications is for areas needs a high heat resistance, low thermal expansion and high electrical or thermal conductivity. Heat sink and electrical contacts are produced from Pan-Ocean. |

|

Standard items from Pan-Ocean for Tungsten are as following:

| Material Type |

Dimensions |

Thickness mm |

Width mm |

Length mm |

Forged |

Bar |

Dia.200-100 |

|

600 |

Dia.100-60.0 |

|

1000 |

Dia.60-30 |

|

2000 |

Rod |

Dia.2.0-30.0 |

|

2500 |

Wire |

Dia.0.1-6.0 |

|

Coil |

Rolled |

Plate |

>3.0 |

600 |

L |

Sheet |

1.0-3.0 |

600 |

2000 |

0.2-1.0 |

650 |

2540 |

0.1-0.2 |

400 |

1000 |

Foil |

<0.1 |

150 |

Coil |

Fabricated |

Components |

hot zone, power semiconductor substrate, glass sealing and melting electrode, components and assemblies for thin film deposition system, ION implanting system, X-ray tube anode, heat sink. |

Tantalum |

Tantalum is a metal of atomic number 73, melting point is 3017°C (5463°F), and density is high up to 16.68g/cm3. Tantalum is blue-gray, dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity; it also behaves excellent corrosion resistance in most acids and caustics.

Tantalum alloy

Ta-2.5W (RO5252)

This alloy is particularly useful in applications where low temperature strength is important along with high corrosion resistance and good formability, offering higher strength than pure tantalum while maintaining the fabricate characteristics.

Ta-10W (RO5255)

This alloy should be considered when high temperatures of up to 2480°C (4500°F) and high strength in a corrosive environment are required. The alloy has approximately twice the tensile strength of pure tantalum and yet retains tantalum's corrosion resistance and a good portion of tantalum's ductility.

Tantalum and tantalum alloy are showing excellent corrosion resistance, heat transfer properties and workability. It performs both heat resistance and corrosion resistance in a very long period operation, and can be used stably in hydrofluoric acid and strong hot alkali. Its corrosion resistance is similar to glass, and mostly recommended to be used as heat exchanger, condenser, reactor, columns, components for fluid line and valves in extremely hot and corrosive industries. |

|

Standard items from Pan-Ocean for Tantalum and tantalum ally are as following:

Material type |

Specifications |

Thickness mm |

Width mm |

Length mm |

Plate |

ASTM B708 |

3.0-10.0 |

1000 |

2000 |

Sheet |

ASTM B708 |

0.1-6.0 |

600 |

2000 |

Foil |

ASTM B708 |

0.05-0.1 |

150 |

2000 |

Rod |

ASTM B365 |

Dia.4.0-120.0 |

|

L |

Wire |

ASTM B365 |

Dia.0.25-4.0 |

|

Coil |

Tube |

ASTM B521 |

Dia.3.0-120.0 |

wall 0.2-5.0 |

6000 |

Components |

Components and parts as well as assemblies as per customers’ specific requirements and drawings used in various areas in electronics, corrosion devices, high temperature furnace and lab, inspection instruments. |

Niobium |

Niobium is a soft and ductile metal, shiny and white in color, Niobium has physical and chemical properties similar to tantalum, but the density of niobium is 8.6g/cm3 about half of tantalum, and it is a good substitute of tantalum since it is cheaper and lighter.

The machining characteristics of niobium is similar to those of stainless steel, both high-speed and carbide tools can be recommended for machining, however it does have a tendency to gall, tear and weld to the face of the cutting tool, it is important to use water-soluble cutting oils for cooling in operating. Deep drawing, punching and deformation are easy to be obtained in fabrications.

Niobium is extremely corrosion resistant in demanding applications and heat resistant in high temperature areas, it performs excellent heat transfer properties and exceptional durability for many years operating.

It is widely used and a good Tantalum substitute since it is cheaper and lighter, these applications including: superconducting materials, furnace parts, thin-film substrates, electrical contacts, heat sinks, reaction vessel, condenser, heat exchanger, steam heating elements, evaporating boats, sputtering target. |

|

Standard items from Pan-Ocean for Niobium and niobium alloy are as following:

Material type |

Specifications |

Thickness mm |

Width mm |

Length mm |

Plate |

ASTM B393 |

3.0-10.0 |

1000 |

2000 |

Sheet |

ASTM B393 |

0.1-6.0 |

600 |

2000 |

Foil |

ASTM B393 |

0.05-0.1 |

150 |

2000 |

Rod |

ASTM B 392 |

Dia.4.0-120.0 |

|

L |

Wire |

ASTM B 392 |

Dia.0.25-4.0 |

|

Coil |

Tube |

ASTM B521 |

Dia.3.0-100.0 |

wall 0.2-5.0 |

6000 |

Components |

furnace parts, thin-film substrates, electrical contacts, heat sinks, reaction vessel, condenser, heat exchanger, steam heating elements, sputtering target. |

Zirconium |

Zirconium is a lustrous, grey-white, strong transition metal with very good properties of soft, ductile and malleable even at room temperature. Zirconium is highly resistant to corrosion by alkalis, acids, salt water and other agents.

In nuclear reactor of commercial power generation station, Hafnium-free zirconium has been used as a low absorption cross section for thermal neutrons,

Commercial-quality zirconium for most uses still has a content of 1% to 3% hafnium, and this contaminant is unimportant except in nuclear applications. The most commercial applications for zirconium are being used as re-boilers, evaporators, tanks, packings, trays, reactor vessels, pumps, valves and pipeline in the chemical processing industry.

|

|

Hafnium |

Hafnium is a shiny, silvery, ductile metal, the chemistry of hafnium and zirconium is so similar that the two is the most difficult to separate on the basis of differing chemical reactions in all the elements, but zirconium impurities affect its physical properties and its nuclear properties, and there is no significant affection for commercial grade hafnium with Zirconium content 1%- 3%.

Hafnium has a good mechanical properties and extremely corrosion resistant as well as excellent nuclear absorption properties for thermal neutrons (almost 600 times that of zirconium). It is typically used as control rods in nuclear reactors, also because of similarity between zirconium and hafnium, it makes the possibility to employ zirconium instead of hafnium in most applications, from the engineering ceramics, hafnium carbide is the most refractory binary composition known with the highest melting temperature of 4215°C.

Hafnium is also used as the electrode in plasma cutting. |

|

|