Leading Titanium Supplier

--------------- ----------------for Commercial Applicaiton

|

|

Titanium has a melting point of 1660°C(3020K), specific gravity of 4.51g/cm3, it is a low density, strong, lustrous, corrosion-resistant (including sea water, aqua regia and chlorine) transition metal with a silver color.

The corrosion resistance of titanium is due to a stable, protective, strongly adherent oxide film layer. This film forms instantly when a fresh surface is exposed to air or moisture. This film growth is accelerated under strong oxidizing conditions. The titanium oxide film is capable of healing itself instantly in the presence of moisture or oxygen.

The two most useful properties of the metal form are corrosion resistance and the highest strength-to-weight ratio of any metal. In its unalloyed condition, titanium is as strong as some steels, but 45% lighter, and is resistant to dilute sulfuric and hydrochloric acids, moist chlorine gas, most organic acids, and chloride solutions.

Titanium can be alloyed with iron, aluminium, vanadium, molybdenum, palladium and other metals to produce strong lightweight alloys for aerospace, military, industrial process, automotive, sports, food and medical devices, orthopedic implants, dental and endodontic instruments and files, electronics, and other applications. The highest tensile strength for titanium alloy Grade 5 can reach to 895 Mpa (130 ksi).

|

Typical titanium grade and physical properties in annealed condition

| Titanium Grade |

Tensile strength min |

Yield strength min. |

Elongation rate |

ksi |

Mpa |

ksi |

Mpa |

min, % |

Grade 1 |

35 |

240 |

20 |

138 |

24 |

Grade 2 |

50 |

345 |

40 |

275 |

20 |

Grade 3 |

65 |

450 |

55 |

380 |

18 |

Grade 4 |

80 |

550 |

70 |

483 |

15 |

Grade 5 (6Al-4V) |

130 |

895 |

120 |

828 |

10 |

Grade 7 |

50 |

345 |

40 |

275 |

20 |

Grade 9 (3Al-2.5V) |

90 |

620 |

70 |

483 |

15 |

Grade 12 |

70 |

483 |

50 |

345 |

18 |

Grade 23 (6Al-4V ELI) |

120 |

828 |

110 |

759 |

10 |

|

|

|

|

|

|

Material sheet of Titanium and titanium alloy from Pan-Ocean

Forms |

Dimensions mm |

Specifications |

|

Plate |

2.5-16 x 800-1500 x 12000 |

ASTM B265, AMS4902 |

|

Sheet |

0.6-3.0 x 800-1400 x 5000 |

ASTM B265, ASTM F136, ASTM F67, AMS4902 |

|

Coil |

0.5-3.0 x 800-1250 |

ASTM B265 |

|

Bar |

Dia.30-400 x 5000 |

ASTM B348, ASTM B381, MIL-T-9047, AMS4928 |

|

Rod |

Dia.3.0-40 x 3500 |

ASTM B348, ASTM F136, ASTM F67 |

|

Wire |

Dia.0.1 x 7.0 |

ASTM B863 |

|

Tube |

Dia.3.0-350 x 0.2-5.0 x 15000 |

ASTM B338, ASTM B861, AMS4903, ASTM B337 |

|

APPLICATION

Industrial Application |

Titanium is characterized with high corrosion-resistance, heat resistance, high strength, and a density of approximately 60% that of steel. These properties make titanium an excellent material of choice for many industrial applications in chemicals of chlorites, hydro chlorites, chlorates and chlorine dioxide, and propeller shafts and rigging and heat exchanger of desalination plants, as well as heat and corrosion equipments in power generation, marine, chemical and pulp/paper industries.

Highly efficient gas turbine engines are possible only through the use of titanium-based alloys in components like fan blades, compressor blades, discs, hubs and numerous non-rotor parts. The key advantages of titanium-based alloys in this application include high strength/weight ratio, strength at moderate temperatures and good resistance to creep and fatigue.

A major industrial application for titanium remains in heat transfer applications in which the cooling medium is seawater, brackish water or polluted water. Titanium condensers, shell and tube heat exchangers, and plate and frame heat exchangers are used extensively in power plants, refineries, air conditioning systems, chemical plants, offshore platforms, surface ships and submarines.

The life span and dependability of titanium are demonstrated by the fact that of more and more designing engineers select titanium to use in various applications because of excellent performance in corrosion and heat resistance and high performance-price-ratios. |

|

Chlorine Gas and Chlorine Chemicals |

Titanium and titanium alloys are highly resistant to chlorine and chlorine chemicals because of their strongly oxidizing natures, the corrosion resistance of Titanium in chlorine gas and chlorine containing solutions results a large amount of Titanium installations. In many years experiences with evidence, titanium has earned a reputation for high performance and cost-effectively replaced stainless steels, nickel alloy, copper alloys and other metals in this service.

Typically electro-chlorination systems are being used in the treatment of power station, desalination plant, coastal installation, ballast water, marine sewage, swimming pool, potable water, and most components and parts for these systems including: anodes, vessels, columns, pipeline, pumps, valves and fittings. |

|

Fresh and Sea Water |

Titanium metal contains a surface layer of titanium oxide that prevents chemical reactions, it resists all forms of corrosive attack in fresh and sea water to temperatures of 260°C (500°F).

Titanium is present as an action in acidic solutions and can therefore be removed by means of ion exchange. Iron vitriol that is formed in titanium dioxide pigment production is processes to acid or oxide and can than be applied as a precipitant in water purification.

In fresh water generation system, a titanium plate assemblies is taken to be used in the processing of thermal desalination for fishing travelers, deep sea going vessels, island based resorts, marine ships, on shore based installations.

Titanium also has proven to be one of the best performers when it comes to selecting materials for use in various seawater environment. |

|

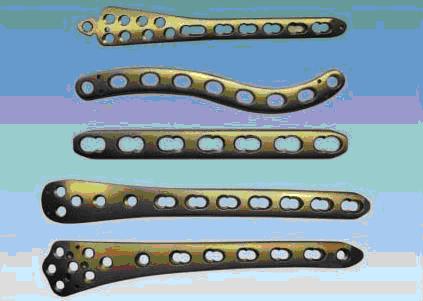

Medical |

Titanium has many useful features including low specific gravity, half that of nickel, excellent corrosion resistance and strength, high biocompatibility, and non-magnetic properties, with these advantageous features, titanium is an optimum material to be used in different applications for medical applications including surgical implements and implants, such as hip balls and sockets, surgical instruments, dental roots and jigs, medical wheel chair and bed, and devices for medical and pharmacy processing. |

|

Sport |

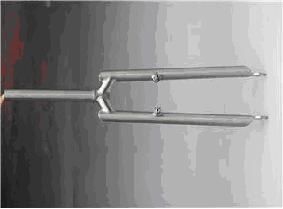

Because of it’s high strength and low density characteristics, combined with corrosion assistance, titanium offers many attractions for automobile and bike applications,

The enhanced performance desired from use of titanium in racing car significantly attract the engineer to choice titanium to fabricate connecting rods, reduced-weight valves, mufflers, springs, and exhaust pipe headers. By using of titanium, it enables designs to achieve fuel economy efficiency, reduced engine noise, vibration and improved durability due to reduced components weights.

In the area of titanium bicycles, Eddie Merckx, the greatest cycling champions of all times, was the first sportsman to use titanium bicycle in the 1972 edition of Tour de France. The advantages of titanium used in bicycle is subject to achieving diminished weight, shock absorbing capabilities, returning the energy of the road impact, and long life span because of better fatigue strength corrosion assistance.

The titanium alloy of choice for bicycles is titanium grade 9 (Ti3AL2.5V – titanium, 3% aluminum and 2.5% vanadium).

Titanium is also used in other sporting goods like golf club heads, tennis rackets, and fishing rod and line. |

|

|

|

|

| | |

|